Here's a snapshot showcasing the finished helmet:

Complete details about the build process after the jump.

To begin this project, I set up my base for sculpting. In this case, I was using a sculpting armature from Monstermakers.com and an old child-sized motorcycle helmet that was laying around in the workshop:

In order to keep the helmet fairly form-fitting while still allowing the wearer to get in and out of it, I decided that the faceplate should be removable. After a few hours of tinkering with the main portion of the helmet, here's what I had:

To get an idea of what I was going to build, I made a mockup of the faceshield out of cardstock paper:

This is the point when the Navy called me up to go and help out with Operation Tomodachi. I dropped everything and flew off to Okinawa for a month and a half worth of work with the 7th Fleet Commander's staff aboard the USS BLUE RIDGE.

When I returned, I rolled right into preparations for the Maker Faire and this project stayed on the backburner. It got some tinkering attention here and there, but it was still a while before I got back to work on it.

While I continued sculpting the main portion of the helmet in clay, I built the faceshield prototype out of sheet styrene heated and bent to shape:

In order to be as accurate to the game as possible, the visibility in this helmet was going to be awful. Still, these are the sacrifices you make in order to look good.

Here's a couple more shots to show progress during the sculpting:

As you can see in the above pic, I'd started adding Bondo auto body filler to the faceshield in order to smooth out parts of it and add thickness here and there. I also added a few more tabs and notches with more scraps of sheet styrene that I had in the shop. Here's a shot showing some of the details:

At this point I'd call the sculpt about 75% done. There were still some fine details that needed sorting out and some symmetry issues for the rest of helmet. Still, it was definitely looking the part:

By now it had reached what I call the "zit stage." This is that point in a project where, no matter how much you mess with it, it's not going to get better and it may well end up looking a lot worse.

I still kept tinkering with it though:

Sometimes I just can't help myself...

When I finally talked myself into not screwing with it anymore, I sprayed the faceplate with my customary shade of light red that I use for all of my prototypes:

This made it nice and shiny:

With the faceplate as perfect as I'd get it, it was time to focus on the details on the back of the helmet:

Here you can see some of the details coming together:

Here's a shot showing some refinement to the sides of the helmet:

At this point it was starting to become painfully obvious that I really could've used some higher resolution reference images. Oh well.

Here's the last picture of me tinkering with the sculpt:

I was so excited to get to the moldmaking stage that I neglected to get final pictures of the back of the helmet sculpt. You'll see how it looked later on.

For the faceplate I'd decided to make a two-piece mold so they can be cast with a controlled thickness. Meanwhile, the rest of the helmet would just be rotocast in a mold made the same way as my Star Wars Republic Commando helmet.

Here's the faceplate going under the rubber:

When laying up silicone on a mold like this, the first layer is referred to as a "print coat" or "detail coat." This is where all of the tiny details will be imprinted into the rubber. In order to make sure the silicone gets into every nook and cranny, you need a batch of pourable silicone (with the plurple catalyst). The problem is that it will run all over the place:

To combat this tendency, you need to constantly brush it back up onto the top and sides of the piece you're molding. Here I am brushing silicone back up onto the dome of the helmet:

Since I don't like spending all day at war with gravity, I also add a bit of accelerator to the catalyst so the rubber will cure faster. The more you add, the faster the rubber cures. Unfortunately, it also means that the cured rubber will be a bit stiffer (not always a problem) and weaker (always a problem).

Even with the accelerated cure time, this stage can get a bit messy. Here's the faceplate with plurple rubbery goop all over the place:

Here's the dome after the silicone had started to set up:

Here's the faceplate with a quick layer of pink thixotropic silicone:

And here's the dome:

Just to be sure there were no thin spots, the next step was to do another layer of pink silicone over everything. Into this I went ahead and set blocks of cured silicone cut from retired molds. Then I went ahead and brushed another layer of plurple silicone over everything just to make sure it'd be nice and smooth. So here's how it looked at the end of the day:

The mold on the right is for my Star Wars Republic Commando helmet. I like to do molds all at once so I'm not tempted to spray paint or blow grinding dust all over the fresh silicone.

The mold on the right is for my Star Wars Republic Commando helmet. I like to do molds all at once so I'm not tempted to spray paint or blow grinding dust all over the fresh silicone.Once the rubber had cured, the next step was to turn the helmet sculpt completely upside-down and reinforce the lower edges with more pink silicone:

With the rubber thick enough to survive a few pulls, the next thing I did was build a two-part mothermold out of fiberglass:

I also made a mothermold for the faceplate:

If any of you reading this work with fiberglass in a professional capacity, I'm sure you're thinking "that's the worst fiberglass layup I've ever seen," and you're right. Fortunately, I don't need it to be all that good. I just need something to keep the rubber jacket lined up.

Here I am pulling the rubber jacket off of the helmet sculpt:

The sculpt did not survive the de-molding process. But turned inside out, the mold looked pretty good:

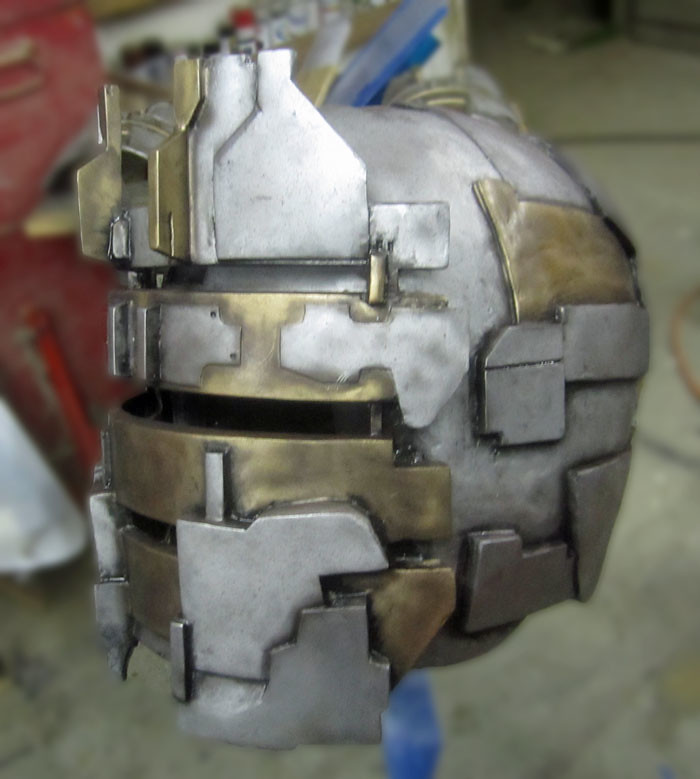

Once the mold for the dome section of the helmet was completed I went ahead and made a casting. It was a success:

Clearly it would need some padding in order to keep it in the right place on my head.

While the mold for the dome was good to go, the faceplate still needed the inside molded. The first step was to turn the whole thing face-down and peel the cardboard off the back side:

Then I removed the clay that had formed the parting wall and built up a clay dam around the edges of the silicone:

Then the silicone got a generous coat of release agent and it was time to start layering up the inside of the mold with more silicone rubber. Here I am slathering on the print coat:

After a bit more layering with silicone, it looked about like so:

Then I laid up a fiberglass shell to go over the inside portion of the mold. Unfortunately, I neglected to take any pictures until after the inner shell had cured and I'd pulled it all apart again.Once the fiberglass had cured, the next step was to drill out bolt holes in the mothermold. These holes would go all the way through the rubber as well as the mothermold halves. that way they would help to keep the two halves of the mold aligned as well as clamped shut.

I needed to drill through the fiberglass, but not the silicone. Running a drill into the silicone would only serve to make a huge mess of things. Instead, I sharpened the end of a piece of hollow brass tubing and used it to cut holes through the rubber.

Then I used an X-acto knife with a sharp new blade to cut pour spouts and bubble vents into the inner portion of the mold:

Then I reassembled the mold without the prototype inside and poured a cast. Once I'd popped it out of the mold, I couldn't resist the urge to try it on:

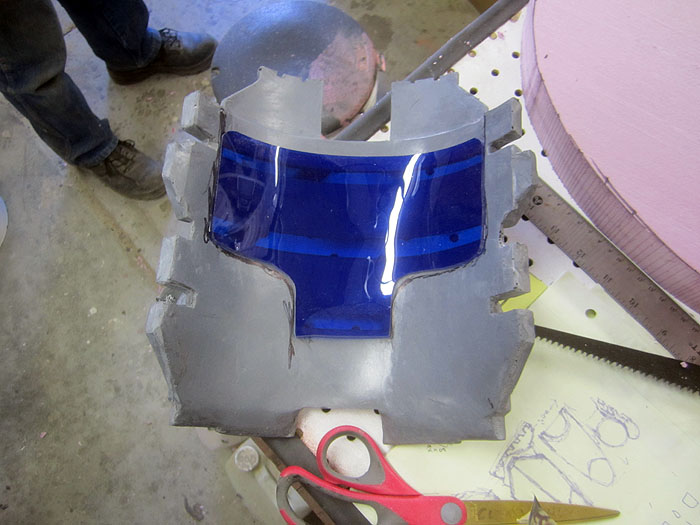

My friend Matt was standing around in the workshop at this point, so I asked him to make a tinted blue acrylic insert for the slots in the faceplate:

The acrylic insert was made by cooking a piece of pre-cut acrylic in a toaster oven until it was flexible enough to conform to the curvature of the faceplate, then laying it in place until it had cooled.

It worked out well enough:

Here's the helmet and faceplate in black primer:

It worked out well enough:

Here's the helmet and faceplate in black primer:

At this stage, I fitted rare earth magnets to the inside of the faceplate and matching magnets at the forward edge of the helmet to hold the faceplate on. Unfortunately, I neglected to take pictures.

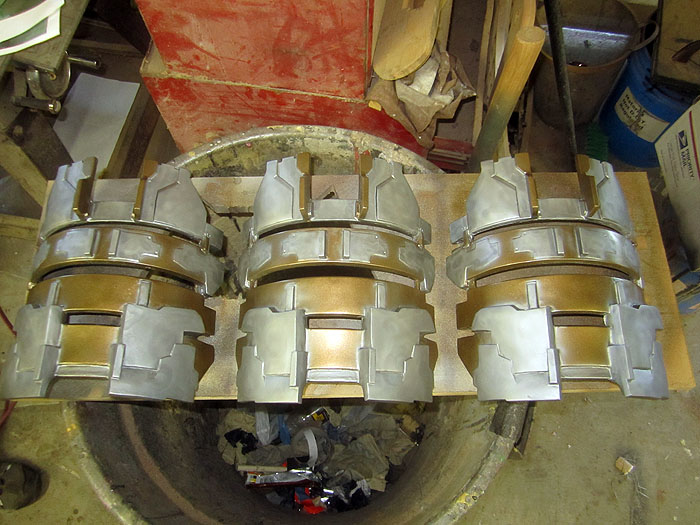

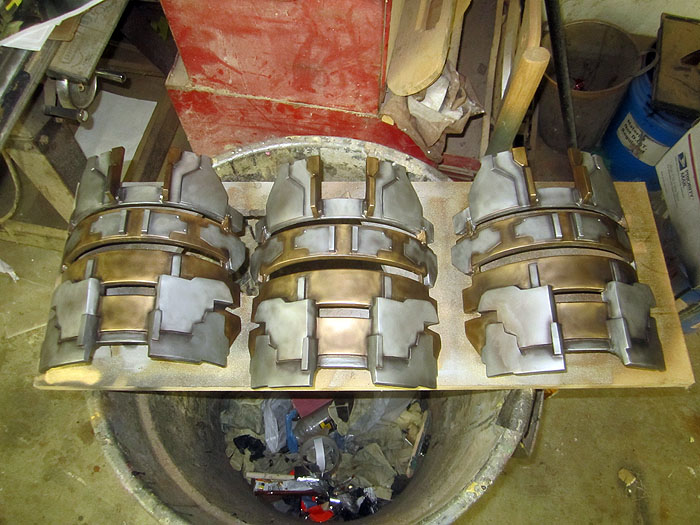

For a base color, I decided on "magnesium" from the Model Masters Metalizer line:

Then I decided I'd be better off with a glossier basecoat and decided to do the bronze first. So everything got a coat of Rustoleum Classic Bronze:

Once the bronze had dried, I went back over it with the airbrush version of the magnesium metalizer:

Then I used the airbrush to pick out some lighter areas in "steel" metalizer:

Since the edges had been completely lost along the way, I mixed up some gold enamel with a bit of rust and went back over the bronze parts to neaten up the edges and give them a bit more depth. Then I used "burnt iron" metalizer to add some age here and there:

I was pretty happy with the result:

I'm then added a quick blackwash to weather the whole thing and a misting of black primer and then red primer to give it that just-finished-battling-necromorphs-all-day look:

Then I ran some electroluminescent tape inside the slits in the visor so it would be properly illuminated:

Believe it or not, I can actually see out of it too.

I'll be building the rest of the suit between now and Halloween. Stay tuned...

Hey, like the new look of the site. Good job. Also, how is the Heart of Gold doing?

ReplyDeleteONE COMMENT?!?

ReplyDeleteI thought this page was so damn long because there were hundreds!

How in the world is your blog not massively popular???

Do want :(

ReplyDeleteThis is amazing.

ReplyDeleteim making this ok?

ReplyDeleteYour work on this is pretty damn cool. I've been using this page as a main inspiration for my own Isaac helmet, although I don't have access to all your tools. As a reference, what was your budget for this project?

ReplyDeleteHonestly, I really don't know. Aside from the EL tape, most of it was stuff I had on hand in the workshop.

DeleteHow much would it take me for you to make me a helmet from dead space 3 the archeologist suit

DeleteThis tutorial is superior!

ReplyDeleteSadly, I don't have references in building my own for my nephew. (Age 7 but already a DIE HARD fan of Dead Space Franchise)

Can you post/email/send us the link of your reference images?

or if you can't How do you take the pictures?

my mail : armando.e.lopez.jr@gmail.com

I'm planning to make one but with rubber sheets. (First time creating a helmet)

The references were all screen captures from YouTube videos.

ReplyDeletehey man, i see that you possibly live in petaluma, i live very close to there myself.i was a little curious as if you would want to sell that helmet?i would be stoked to buy it!

ReplyDeletewhat material did you use?

ReplyDeletelike this, but can you make one for a motorcycle just like this and in black and gray shades? Ill buy it... if anything email me srivan01@yahoo.com

ReplyDeleteYou're so cool! I don't suppose Ive learn something like this before. So good to seek out anyone with some authentic ideas on this subject. realy thank you for starting this up. this web site is something that’s wanted on the web, someone with somewhat originality. helpful job for bringing one thing new to the web!

ReplyDeletehard hat

your company is entirely based on making awesome and detailed/legit things? can i work for you? i'm currently going to school for drafting and i wanted to start my own business like this one making pretty much whatever people ask for: houses, motorcycles, helmets, movie/videogame props, furniture, clothing, inventions etc. i'm already a pretty good do-it-yourselfer but i don't have access to your advanced tools. i didn't know places like this existed and i'm sure my resume doesn't match your high standards yet, but i was just curious if you think you might be hiring people in the future when your company expands.

ReplyDeleteneksajiehst@gmail.com

-jeremy hansen.