Some time ago I got very hooked on the Star Wars video game Republic Commando

on the XBox. The game is a squad-based shooter in which you play the leader of a team of clone commandos, specialized clone troopers at the outset of the Clone Wars. The game begins at the end of Star Wars: Episode II

on the XBox. The game is a squad-based shooter in which you play the leader of a team of clone commandos, specialized clone troopers at the outset of the Clone Wars. The game begins at the end of Star Wars: Episode II  and carries you through all sorts of campaigns that took place before the beginning of Episode III

and carries you through all sorts of campaigns that took place before the beginning of Episode III .

.

I got so hooked on the game that, in a very rare-for-me foray into the expanded universe of Star Wars novels, I actually found myself reading the novels which were based on the video game

which were based on the video game  which in turn was based on a set of characters which didn't even appear in the movies

which in turn was based on a set of characters which didn't even appear in the movies  to begin with. Before this happened I could at least claim that, while I was a huge geek, at least I wasn't geeky enough to read any of the Star Wars novels. This game is what pushed me past that particular point of no return (as if owning a suit of custom stormtrooper armor* wasn't enough already).

to begin with. Before this happened I could at least claim that, while I was a huge geek, at least I wasn't geeky enough to read any of the Star Wars novels. This game is what pushed me past that particular point of no return (as if owning a suit of custom stormtrooper armor* wasn't enough already).

Since my affinity for these Republic Commandos wasn't about to go away, I decided I might as well build my own rendition of the costume. So a while back I started building a pepakura helmet based on a model from Skip's Pepakura files. When I say "a while back," what I mean is something like November of 2009. Here's how it started:

Once the pepakura model was built, I was pretty happy with the sizing:

Here's a side shot:

If anyone's wondering about the scale of this thing, I'm 5'7" tall with an average build.

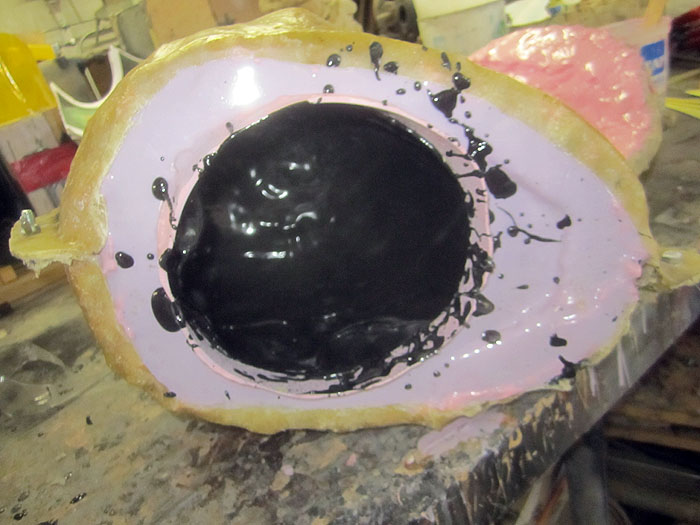

All of the papercraft work was done while I was out at sea working on a container ship. Once I'd returned home, the model had gotten a bit mangled. Since I was never especially happy with the shape of the dome, this wasn't terribly heartbreaking. Instead, it provided the perfect excuse to cut up the model and splice it onto a child-sized skateboard helmet. Once it was securely attached, I layered on a whole lot of Bondo:

Because I have a tendency to jump the gun on things like this, once I'd done a bit of fairing and sanding, I couldn't resist the urge to put a coat of black primer on the whole thing:

And as long as I wasn't resisting urges, I went ahead and tried it on again:

After that, it alternated between hanging on the wall where it wasn't being worked on and sitting on the bench where it wasn't being worked on. Occasionally I'd have a bit of down time, notice it staring at me, and spend ten or fifteen minutes sanding it or spraying another coat of primer on it. But in all honesty, this was just a backburner project for well over a year.

Then I decided it was starting to annoy me. For no reason I can think of, this particular project seemed to somehow represent everything I was neglecting. It just sat there staring at me, taunting me, vexing me. It was as if the helmet was shouting out, "Go on, finish me. I dare you. But you won't. Because you are a failure..."

So despite the fact that I genuinely had more vital things to work on, a couple of weeks ago I pulled it down off the wall. I dusted it off. Resisting the urge to give it another coat of primer, I got back to work. With a bit Bondo and sanding, the whole thing was starting to look pretty sharp:

Then when I scored in the seam lines on the cheeks and cut a few of the notches here and there, it really started to pop. Just to be sure I sprayed it with a coat of white primer:

Thinking I was nearly done, I went ahead and sprayed it with my usual glossy prototype color**:

Here's the "intimidator" shot, looking up at the chin so it's imposing:

Here's a shot of the back:

Once I'd made it shiny and pink, I started noticing all sorts of thing I'd neglected to add to the build. With a bit more tweaking, I added some more notches and the little light widget to the right ear:

The very last thing I added was this little recessed area in back of the cheek hollow:

Finally, I added a couple of fun bits to the underside:

At this point, I'm satisfied with the overall shape and finish of this piece. Unfortunately, it's heavy and it won't hold up to much abuse. It's also pink.

So now it's time to make another mold. Stay tuned for part 2: moldmaking...

*Stormtrooper armor, and a Boba Fett costume, and a TIE pilot costume, and a Darth Vader costume, and three different types of clone trooper helmets, and the list goes on...

**People often ask me why I tend to paint my prototypes pink. The reason is that I want to have a nice smooth finish and the color isn't important. When I first posted pictures of my Master Chief helmet prototype online, I was contacted over and over by folks who wanted to nitpick my color selection. They all disagreed on what shade of green to use, but they still all agreed that I'd gotten it wrong. Since then I avoid this whole argument by making it plainly obvious that I wasn't even trying to get it right.