So we had us a bit of a lull in the workshop schedule and I went ahead and volunteered to take on another build for the folks at Magic Wheelchair.* As usual it took a while to sort out which kid we'd be building for and what event we'd be doing the unveiling at, but eventually it all got sorted.

Meet Aidan:

Meet Aidan:

Aidan wanted to be Sonic the Hedgehog:

Magic Wheelchair was able to get the digital assets used to render Sonic and his racecar in the upcoming video game so we could use them to build the car for Aidan. They gave us a great starting point:

The main challenge: by the time we'd gotten confirmation that Aidan could make it to the event and Sega had provided the digital assets and everything was finally lined up for us to begin building, we only had twelve days to complete the build and have it up on stage for a live reveal at the Licensing Expo in Las Vegas.

Fun.

The next step was for me to take the car apart digitally, remove Sonic, and alter the proportions a bit so we could fit Aidan's wheelchair inside the cockpit while still keeping the whole build small enough to fit through a doorway. The grey cylinder below shows our earliest approximation of the wheels on his wheelchair to give us an idea of how it would fit.

I had my guy Jeff Santos make a few more changes since he's better with digital sculpting than I am. He made the cockpit wider and the body a bit less tall. Then he dialed in a few other details and made the wheel wells circular again since we'd gone and stretched and skewed the body shape. The end result was a cutesy, chibi version of the car that still retained the key features that made it recognizable:

This ate up one of our twelve days.

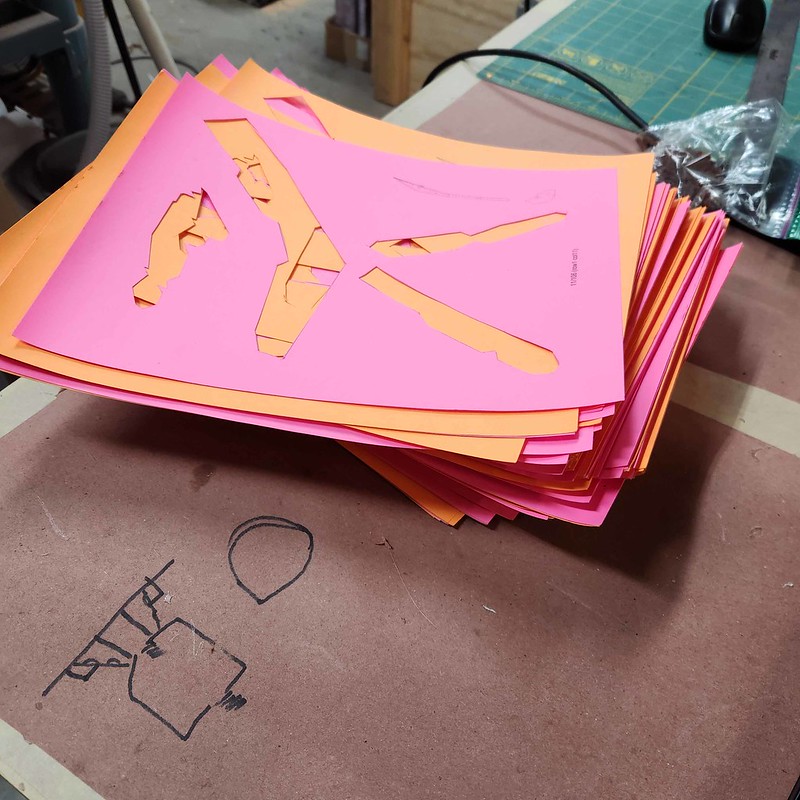

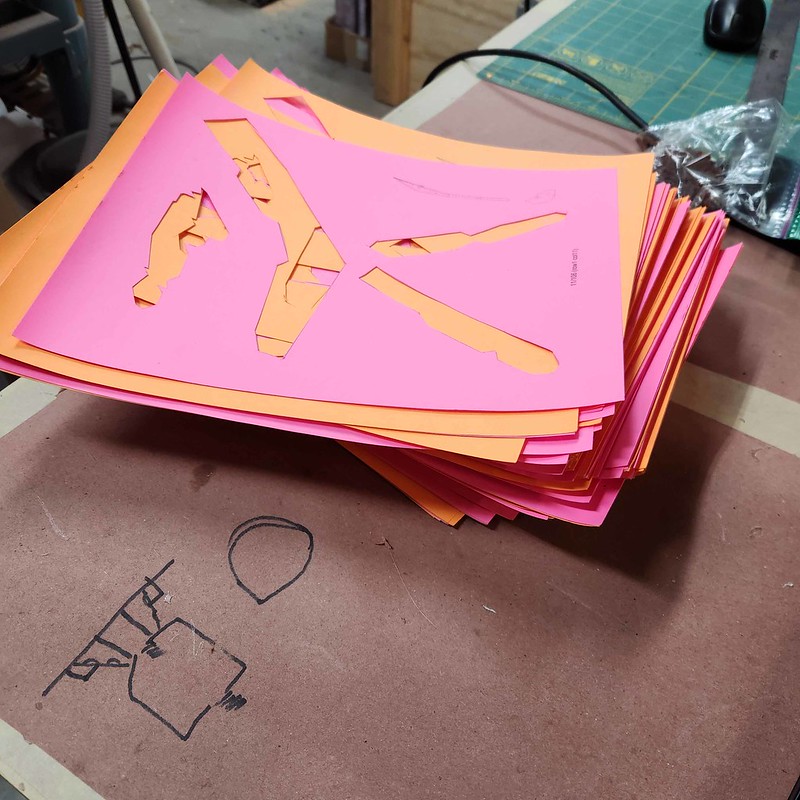

We set the orange printed stack on one side of the table and the pink stack on the other side of the table and got to cutting:

The pages were separated into sequential 20-page stacks in order to make sure we didn't lose any of the parts:

On one end of the table I set up two laptops so we could refer back to the original model and page layout in order to identify which part needed to be cut out next:

Then we'd find the corresponding page, cut out the required part, score and fold it, and glue it onto the rest of the assembly in progress:

By the end of day one, we had assembled a big chunk of the rear end:

At the end of day two we had a pretty good chunk of the rear fenders done as well:

The next day was a Monday and most of the volunteers had to go back to their regularly scheduled day jobs. Fortunately, Tia was still available to help me with the paper build:

Here's a shot of me slowly losing my mind as we made progress on the front fenders:

The end of the third day of papercrafting had two pieces that looked like so:

Here's an overall shot of our workspace as I was leaving that night:

At some point on the fourth day of pepakura building, all of the parts were cut out and glued together.

Here's the stack of leftover paper with all of the parts cut out:

It was not small:

But there was only so much time to reflect on that part of things. Instead we got to work attaching the halves together:

Things were really coming together at this point:

In order to keep the wheel wells circular, we wedged a five gallon bucket into each one. Then we stapled the paper car body down onto the tabletop and applied an epoxy hard coat over the whole thing:

Then the hardcoat was left to cure overnight:

The next morning we removed the buckets and the whole thing was still standing:

Even after we removed the buckets from the wheel wells:

The hardcoat would do a lot to keep the paper from crumpling, but we'd need the body to be stiffer in order to do the bodyshop work we'd need in order to fair it all out. So the next step was to layer over the whole exterior with fiberglass:

This filled the recesses in the paper build and allowed us to turn the faceted, low-polygon model into the smooth, curved body we needed it to be without adding too much weight:

Initial shaping was done with saws, then body rasps and files, then finally sanding blocks:

With the foam mostly carved to the shape we needed, it was time to layer on the Bondo. Here's Tia during the initial application:

Here's Jeff smoothing one of the layers:

At this point we had two days left in the shop before we had to hit the road.

The next morning we got to fine sanding on the primered body:

After a quick coat of sealer, it was time to start painting.

This would've been a great opportunity to try out the new paint booth. Unfortunately, since it's a nice, clean space full of horizontal surface, it had a few cars parked in it and I didn't have time to solve the slide puzzle and get enough space to start spraying. Instead, I opted for laying down the color coat in the field outside the shop:

Yeah:

Once the color coat had flashed off, I masked and sprayed the black portions:

Then the white:

Here it is in the shop waiting on the absolute minimum amount of cure time before I could spray on the clearcoat:

Then, under cover of darkness, I applied the clearcoat:

It's so shiny:

So shiny:

Somewhere in the midst of all that madness, Jeff made me digital models of the tires and rims. These were fed to my Carvewright CNC machine to make vacforming bucks:

It turns out they were exactly all I could fit on the 2x2 forming platen:

Fortunately, the parts came out beautifully in high impact polystyrene:

We could've done them as single parts, but making the rims separate made painting them a lot easier and faster:

Once the paint had firmed up, we got to adding the last little detail bits. For example, we scrapped four little flashlights and used their innards to make the headlights:

Tia took some time to touch up the edges of the paint before we sealed the headlights behind a formed plastic lens:

The headlight lens and the windshield were both formed out of PETG, the same kind of plastic used to make plastic soda bottles. The dashboard and steering yoke were 3D printed and that was just about a done thing:

Here's me and the crunch time crew on the last night in the shop:

Then, moving as delicately as possible to avoid damaging the soft paint, we went ahead and loaded into the back of a large SUV we'd rented for the trip to Vegas.

If you're wondering where Rachel was during the latter portion of the build, she was sequestered in the other room, losing her mind while making a really big, custom Sonic plush toy:

This is pretty much how she looked for most of the project:

There was a wire armature built into the arms and legs so it would be poseable and a pipe spine to hold the weight of the head:

Rachel made everything except for the 3D printed feets which we painted to match the rims on the wheels:

Anyway, with all that done, we set out the following morning. Just me, Jeff, Rachel, and the open road:

Rachel spent the bulk of the drive in the passenger seat putting finishing touches on the Sonic plush:

We arrived at the Mandalay Bay Convention Center and finally got a hold of Aidan's wheelchair for the first time. This gave us a chance to build the final bracket that would be lashed onto the bottom of his chair so the car could be mounted in place on top:

The next day we did the reveal:

Aidan seemed a little overwhelmed:

To further celebrate this little guy, he got to lead a parade of all of the mascot characters that were at the event:

There were a lot of costumed characters. Here's about half of them:

In the end it seems like he had a good time:

Later that afternoon I finally had a chance to catch my breath and see the view from our hotel room:

Then, with all said and done, enjoyed a glass of water more than anything else I'd drank in the past year:

That was right before getting the first full night's sleep I had had in two weeks.

The main challenge: by the time we'd gotten confirmation that Aidan could make it to the event and Sega had provided the digital assets and everything was finally lined up for us to begin building, we only had twelve days to complete the build and have it up on stage for a live reveal at the Licensing Expo in Las Vegas.

Fun.

So this project was going to start in crunch time and continue to be a mad scramble all the way through. At one point, while we were talking through the build plan in the shop and deciding on what processes and materials we could use to turn these bits and bytes into pieces and parts, I said something which I instantly knew I'd regret:

"There's not enough time for rapid prototyping, we're going to have to build the whole body by hand."

Sometimes irony can be painful.

The next step was for me to take the car apart digitally, remove Sonic, and alter the proportions a bit so we could fit Aidan's wheelchair inside the cockpit while still keeping the whole build small enough to fit through a doorway. The grey cylinder below shows our earliest approximation of the wheels on his wheelchair to give us an idea of how it would fit.

I had my guy Jeff Santos make a few more changes since he's better with digital sculpting than I am. He made the cockpit wider and the body a bit less tall. Then he dialed in a few other details and made the wheel wells circular again since we'd gone and stretched and skewed the body shape. The end result was a cutesy, chibi version of the car that still retained the key features that made it recognizable:

This ate up one of our twelve days.

Then, for the first time in a long time, we went ahead and cleared off both of the bigger benches in the shop. The emptiness was almost eerie:

Then, harking back to fabrication methods I haven't really used in half a decade, I went ahead and took Jeff's altered version of the car model, cut it in half, imported it into Pepakura, and unfolded it:

I spent most of a day trying to lay out the parts and arrange the seams in a way that would make sense. Given the size and complexity of the model, I would've liked to spend more time refining it at this stage, but we really needed to get to work on the physical parts of the build. According to the software, it was going to take 106 sheets of letter-sized paper to print each half of the body. Each half would contain 434 parts. Each of those parts would have to be cut out, scored along the fold lines, folded, and then glued to the adjacent pieces.

So the next day I printed a full set of the parts on orange cardstock and another full set on pink cardstock so we would be able to tell them apart. Here's the orange parts printed out:

So the next day I printed a full set of the parts on orange cardstock and another full set on pink cardstock so we would be able to tell them apart. Here's the orange parts printed out:

We set the orange printed stack on one side of the table and the pink stack on the other side of the table and got to cutting:

The pages were separated into sequential 20-page stacks in order to make sure we didn't lose any of the parts:

It was slow going at first, but a few hours later we had the whole team working on it:

On one end of the table I set up two laptops so we could refer back to the original model and page layout in order to identify which part needed to be cut out next:

Then we'd find the corresponding page, cut out the required part, score and fold it, and glue it onto the rest of the assembly in progress:

By the end of day one, we had assembled a big chunk of the rear end:

At the end of day two we had a pretty good chunk of the rear fenders done as well:

The next day was a Monday and most of the volunteers had to go back to their regularly scheduled day jobs. Fortunately, Tia was still available to help me with the paper build:

Here's a shot of me slowly losing my mind as we made progress on the front fenders:

The end of the third day of papercrafting had two pieces that looked like so:

Here's an overall shot of our workspace as I was leaving that night:

At some point on the fourth day of pepakura building, all of the parts were cut out and glued together.

Here's the stack of leftover paper with all of the parts cut out:

It was not small:

But there was only so much time to reflect on that part of things. Instead we got to work attaching the halves together:

Things were really coming together at this point:

In order to keep the wheel wells circular, we wedged a five gallon bucket into each one. Then we stapled the paper car body down onto the tabletop and applied an epoxy hard coat over the whole thing:

Then the hardcoat was left to cure overnight:

The next morning we removed the buckets and the whole thing was still standing:

Even after we removed the buckets from the wheel wells:

The hardcoat would do a lot to keep the paper from crumpling, but we'd need the body to be stiffer in order to do the bodyshop work we'd need in order to fair it all out. So the next step was to layer over the whole exterior with fiberglass:

Once that had set up, we added a coat of expanding foam over the outside and started carving it to shape:

This filled the recesses in the paper build and allowed us to turn the faceted, low-polygon model into the smooth, curved body we needed it to be without adding too much weight:

Initial shaping was done with saws, then body rasps and files, then finally sanding blocks:

With the foam mostly carved to the shape we needed, it was time to layer on the Bondo. Here's Tia during the initial application:

Meanwhile, the rest of us smoothed out the body and got it in primer:

At this point we had two days left in the shop before we had to hit the road.

The next morning we got to fine sanding on the primered body:

After a quick coat of sealer, it was time to start painting.

This would've been a great opportunity to try out the new paint booth. Unfortunately, since it's a nice, clean space full of horizontal surface, it had a few cars parked in it and I didn't have time to solve the slide puzzle and get enough space to start spraying. Instead, I opted for laying down the color coat in the field outside the shop:

Yeah:

Once the color coat had flashed off, I masked and sprayed the black portions:

Then the white:

Here it is in the shop waiting on the absolute minimum amount of cure time before I could spray on the clearcoat:

Then, under cover of darkness, I applied the clearcoat:

It's so shiny:

So shiny:

Somewhere in the midst of all that madness, Jeff made me digital models of the tires and rims. These were fed to my Carvewright CNC machine to make vacforming bucks:

It turns out they were exactly all I could fit on the 2x2 forming platen:

Fortunately, the parts came out beautifully in high impact polystyrene:

We could've done them as single parts, but making the rims separate made painting them a lot easier and faster:

Once the paint had firmed up, we got to adding the last little detail bits. For example, we scrapped four little flashlights and used their innards to make the headlights:

Tia took some time to touch up the edges of the paint before we sealed the headlights behind a formed plastic lens:

The headlight lens and the windshield were both formed out of PETG, the same kind of plastic used to make plastic soda bottles. The dashboard and steering yoke were 3D printed and that was just about a done thing:

Here's me and the crunch time crew on the last night in the shop:

Then, moving as delicately as possible to avoid damaging the soft paint, we went ahead and loaded into the back of a large SUV we'd rented for the trip to Vegas.

If you're wondering where Rachel was during the latter portion of the build, she was sequestered in the other room, losing her mind while making a really big, custom Sonic plush toy:

We had hoped we could find an off-the-shelf version that we could put in the car for display when it wasn't on the wheelchair, but everything we found was way too small. So Rachel started pulling one together from scratch:

This is pretty much how she looked for most of the project:

There was a wire armature built into the arms and legs so it would be poseable and a pipe spine to hold the weight of the head:

Rachel made everything except for the 3D printed feets which we painted to match the rims on the wheels:

Anyway, with all that done, we set out the following morning. Just me, Jeff, Rachel, and the open road:

Rachel spent the bulk of the drive in the passenger seat putting finishing touches on the Sonic plush:

We arrived at the Mandalay Bay Convention Center and finally got a hold of Aidan's wheelchair for the first time. This gave us a chance to build the final bracket that would be lashed onto the bottom of his chair so the car could be mounted in place on top:

The next day we did the reveal:

Aidan seemed a little overwhelmed:

To further celebrate this little guy, he got to lead a parade of all of the mascot characters that were at the event:

There were a lot of costumed characters. Here's about half of them:

In the end it seems like he had a good time:

Later that afternoon I finally had a chance to catch my breath and see the view from our hotel room:

Then, with all said and done, enjoyed a glass of water more than anything else I'd drank in the past year:

That was right before getting the first full night's sleep I had had in two weeks.

And so, with our work done, we made our way home to get ready for the next big thing.

Stay tuned...

*I've done a few of these kids' costume projects for Magic Wheelchair over the past few years. It's a really great organization with a pretty straightforward mission to help promote inclusion and empowerment for kids who use wheelchairs. If you'd like to know more about the organization and how to get involved, check out their website at www.magicwheelchair.org

Stay tuned...

*I've done a few of these kids' costume projects for Magic Wheelchair over the past few years. It's a really great organization with a pretty straightforward mission to help promote inclusion and empowerment for kids who use wheelchairs. If you'd like to know more about the organization and how to get involved, check out their website at www.magicwheelchair.org

Great project! One issue I've had with (much smaller) papercraft models is that they want to "roll up" a bit when there's a large open hole like for a helmet (or this car). How did you figure out the right dimensions to spread it out too? I've thought of making some registration features, or just closing the holes (make it "watertight").

ReplyDeleteIn our case, we spanned the openings with some strips of cardboard or placed buckets in the wheel wells to keep things straight as needed. We also stapled the bottom of the model to the table in order to keep everything aligned properly.

Delete